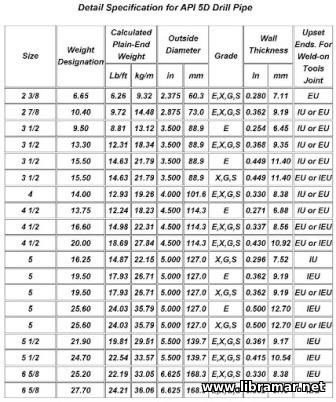

Sizes and Grades of Drill Pipes

Each piece of drill pipe, excluding the tool joint, may have an outside diameter ranging from 2 3/8 to 6 5/8 inches (6.03 centimeters to 16.83 centimeters). Not only does the OD of drill pipe vary, but also the length of the pipe. Manufacturer make drill pipe in one of three API-recommended ranges of lengths. Range 1 lengths vary from 18 to 22 feet (5.49 to 6.71 meters). If a pipe measures, for example, 20 feet (6 meters) long, it would be range 1 length. Range 2 lengths fall within 27 to 30 feet (8.23 to 9.14 meters). Range 3 lengths are from 38 to 45 feet (11.58 to 13.72 meters).

Manufacturers produce these three ranges of lengths because derrick heights vary. The drilling contractor must be able to buy drill pipe lengths that make into stands of a height that fit inside the derrick. He drilling crew needs plenty of height above the stand to be able to manipulate it in the derrick. The most commonly used length of the drill pipe is the range 2 length. Most derricks are from 125 to 150 feet (38.1 to 45.2 meters) which allows a three-joint stand of 30-foot (about 9-meter) joints to fit into the derrick.

Manufacturers produce drill pipe according to API specifications concerning yield and tensile strengths. Minimum yield strength refers to the specific value at which the pipe will permanently distort. Minimum tensile strength refers to a specific value at which the pipe will snap, or pull apart. Drilling contractors determine what type drill pipe they need based on the conditions they expect to encounter downhole. The depth of the hole is the primary factor for determining what grade is needed. Other factors include whether or not the hole is straight or directional and the type of formations being drilled.

Most present-day seamless drill pipe falls into one of four API-grades:

E-75, with a minimum yield strength of 75000 psi (517.125 MPa), a maximum yield strength of 105000 psi (723.975 MPa), and a minimum tensile strength of 100000 psi (689.5 MPa);

minimum tensile strength of 100000 psi (689.5 MPa);

X-95, with a minimum yield strength of 95000 psi (655.025 MPa), a maximum yield strength of 125000 psi (861.875 MPa), and a minimum tensile strength of 105000 psi (723.975 MPa);

G-105, with a minimum yield strength of 105000 psi (723.975 MPa), a maximum yield strength of 135000 psi (930.825 MPa), and a minimum tensile strength of 115000 psi (792.925 MPa);

S-135, with a minimum yield strength of 135000 psi (930.825 MPa), a maximum yield strength of 165000 psi (1137.675 MPa), and a minimum tensile strength of 145000 psi (999.775 MPa).

What these grades tell the drilling crew is the force at which the drill pipe will be managed in some way. The standard grades of pipe have a range of yield strengths (minimum to maximum) but only one minimum yield strength. E-75 includes all drill pipe with a minimum yield strength falling somewhere between 75000 psi (517.125 MPa) and 105000 psi (723.975 MPa), but those minimum tensile strength is 100000 psi (689.5 MPa). If drill pipe has a minimum yield strength of, say, 85000 psi (586.075 MPa) and a minimum tensile strength of 100000 psi (689.5 MPa), it would be classified as E-75 pipe. If, however, it had a minimum yield strength of 100000 psi (689.5 MPa) with a minimum tensile strength of 105000 psi (723.975 MPa), it would be classified as X-95. Obviously, the higher grade drill pipes have higher yield and tensile strengths and can withstand much more forces than the lower grades.

Because of deeper drilling and higher stress levels, a non-standard (i.e. non-API) higher strength drill pipe has been developed – V-150 with a minimum yield and tensile strength of 105000 psi (1034.25 MPa).

In addition to yield and tensile strength, API also provides tables reflecting the torsional yield strength, burst strength, and collapse strength of the four standard grades of pipe. The torsional yield strength of drill pipe is the amount of twisting force a pipe can withstand before twisting off – that is, twisting until it snaps apart. The torsional strength of the pipe itself is usually less than that of the tool joints except when a high-strength drill string is used; all grades above E-75 are considered high-strength.

The burst strength of drill string is the amount of internal pressure that a pipe can withstand before it bursts or springs a leak. The bursting pressure on a drill strength in a well is the sum of the pump pressure applied at the top of the string and the hydrostatic pressure developed by the liquid inside the pipe at a particular depth. If the drill string is open at the bottom, hydrostatic pressures inside and outside the pipe are balanced at any depth. The collapse strength of drill string is the amount of external pressure that a pipe can withstand before it collapses or caves in.

The "Read Later" function allows you to add material to this block with just one click. Just click on the icon and read the articles that interest you at any convenient time.