This booklet is designed for Licensees, ship operators, shipyards, and marine engineers in general, to illustrate the Unified Technical File created for all MAN B&W engines, which is necessary to comply with the IMO regulation aimed at preventing air pollution.

The Unified Technical File serves as a document that outlines a procedure, primarily based on performance measurements, enabling the operator to confirm adherence to the IMO ‘NOx Technical Code’ to the Flag State Authority or their representative when the engine undergoes checks in service. MAN B&W Diesel has developed this booklet to partly elucidate survey procedures and partly serve as a reference manual for IMO definitions.

The initial section focuses on survey routines, from the testbed to the onboard situation, which is crucial for the operator, detailing the survey process from beginning to end. The subsequent section delves into specific topics and how to manage the most common tasks onboard, such as the spare or reconditioning parts addressed by the regulation. For general emission inquiries or emission control of MAN B&W two-stroke engines, references are made to existing materials published by MAN B&W Diesel.

Many of the initial Technical Files created by engine builders differed due to the varying requirements imposed by different classification societies. This variation occurred because the IMO Annex VI does not provide sufficiently detailed guidance on how to compile the Technical File in practice. MAN B&W Diesel has taken on the responsibility of coordinating efforts to prepare a standardized Technical File, intended for use by both licensees and classification societies. This responsibility also encompasses the necessary procedures for shipowners when subsequent engine adjustments or component changes take place.

Men of the ancient world, throughout their historical timeline, were reluctant to venture far from the sea. It was intricately woven into the fabric of their existence, and among their significant contributions to future generations was their mastery of this exceptionally useful yet perilous means of communication. The ancient mariners of the Mediterranean can be credited with most of the major advancements in shipbuilding and navigation that the western world would recognize until the advent of steam power.

The specifics of this accomplishment—the strategies they developed for rowing war galleys, the rigging they created for merchant vessels, the methods they devised for constructing a hull, and similar topics—constitute a highly technical and specialized field, yet one that is closely linked to the daily lives of ancient people. It is no coincidence that the west's first epic poet chose to narrate the tale of a storm-battered captain, and its first historian and dramatist emphasized a pivotal naval confrontation.

Despite the clear significance of this topic, no scholar adequately addressed it until the very end of the last century. In 1895, Cecil Torr published his work, Ancient Ships, which provided a concise yet commendable overview of the knowledge available at that time regarding the design, construction, and equipment of Greek and Roman vessels.

This publication addressed much of the existing gap, but not all; and although Torr promised further studies on other aspects of shipping, he never completed them. Furthermore, due to the increasing volume of new material that archaeologists were continuously discovering, even his contributions quickly became outdated. Subsequently, after World War II, underwater archaeology emerged and began to explore a source of entirely new evidence...

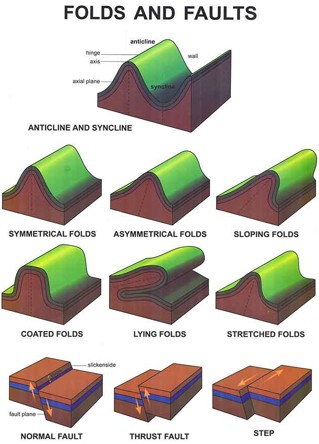

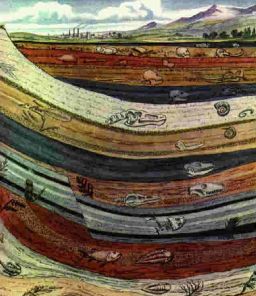

Tectonic plate motion is one of the events that can change the shape and orientation of sedimentary rock layers. Wherever plates converge, the crust is subjected to enormous horizontal forces that can gradually compress it by dozens or even hundreds of miles, wrinkling and folding it like a giant throw rug. The up fold of the crust is an anticline; each down fold is a syncline.

Anticlines and synclines are graphic proof that solid rock can flow like the ice in a glacier. Like most solid materials, rock is slightly plastic under uniform pressure over long periods, it will bend without breaking. However, if stress is applied unevenly or if it exceeds the rock's breaking strength, the rock fractures. A fracture in the crust along which the rocks on opposite sides have shifted relative to each other is termed a fault.

A normal fault is one whose slip plane is at a steep angle with the surface and along which the rock on the upper side has slipped downward in the direction of the dip. In geology, the dip of any surface is the direction in which a marble would roll if placed on it.

A reverse or thrust, fault is one in which the rock on the upper side has been displaced upward along the fault plane. A normal fault allows extension of the crust; it is often caused by forces that stretch the crust. A thrust fault is caused by forces that squeeze the crust together, causing a break where one piece overrides another.

An over-thrust fault is a thrust fault whose slip plane is nearly horizontal its displacement is the result of large horizontal movements of the crust. Along some over-thrust faults, one slab has slipped several miles over the top of another so that a well drilled through the fault would penetrate the same series of rock layers twice.

The ocean has consistently served as a wellspring of grand narratives of endeavor and exploration. Our connection with the sea – encompassing work, play, love, loss, hope, and despair – plays a crucial role in shaping human identity, defining who we are as individuals and as societies.

You can uncover these grand tales of adventure at the National Maritime Museum, located in Greenwich, London – the largest and most frequented museum dedicated to seafaring in the world. Its extensive collection has inspired this book of puzzles, which will guide you on a journey around the globe.

This book features over 100 puzzles, many of which draw inspiration from the museum’s artifacts and their narratives, including maps, ships, nautical terms, explorers, myths, legends, iconography, and maritime traditions. The puzzles will challenge your general knowledge, observational skills, and interpretative abilities along the way.

You may navigate through the book in any sequence you prefer – there is no predetermined path on this journey! Some puzzles may present greater challenges, but you can always continue onward and revisit what you may have overlooked. By the time you reach the conclusion, you will have traversed centuries of history, crossed vast expanses of ocean, and made innumerable discoveries – so secure the hatches and embark on your voyage!

The objective of this questionnaire is to establish a standardized approach for collecting information about ships intended for the use of owners, operators, and charterers of vessels that transport liquefied gases in bulk, as well as for the terminals that handle such ships.

The phrase "Liquefied Gas Carrier" refers to vessels specifically engineered for the transportation of pressurized or refrigerated liquefied petroleum and chemical gases that possess a vapor pressure greater than 2.8 bar absolute at a temperature of 37.8°C, along with other products detailed in chapter 19 of the IGC Code, when transported in bulk, including those chemical carriers authorized for the transport of LPG and chemical gases.

While many owners already supply a ship information questionnaire, this document offers a suitable alternative where one is not available. The use of this questionnaire is entirely at the discretion of individual ship owners, operators, charterers, terminal operators, and other relevant parties.

It is anticipated that the Questionnaire will be completed in full only once during the lifespan of a ship, with minor adjustments to the recorded data being made as necessary should management, systems, or equipment undergo changes. Throughout the Questionnaire, if alternative responses are presented in the text, the response that does not apply should be removed.

As geologists gather information about the structure and character of the rock formations, they arrange it in graphic form. This not only helps them visualize what they cannot see directly, but also provides a way to communicate their findings to others. In particular, it helps them visualize and display the stratigraphy of the crust-information that describes the origin, composition, distribution, and succession of rock layers.

Maps, Sections, and Diagrams

Geologic information can be arranged graphically to show variation either horizontally or vertically. Horizontally arrayed data are maps; vertically arrayed data are sections. Sometimes these two types of arrays are combined in a simulated three-dimensional graph.

A geologist usually starts with a base map of the area of interest, showing survey benchmarks, property lines, and such non geologic surface features as streams, roads, and buildings. Base maps are useful for planning exploration, leasing, road building, well placement, and other activities.

geologic surface features as streams, roads, and buildings. Base maps are useful for planning exploration, leasing, road building, well placement, and other activities.

This Nautical Almanac presents compilation of information prepared by Captain Roberto Iori. A great number of tables are intended to serve as valuable instrument for the navigator. The accuracy of the data contained in these tables has been numerously checked and confirmed; however, it cannot be fully guaranteed so you would better use them as a supplementary tool.

The information contained in the Almanac includes corrections to be applied to the observed altitudes of the Sun and of a fixed star, speed-time-distance table, apparent magnitude, conversion of arc to time, increments and correction tables, and other supplementary information. We strongly recommend students of marine navigation to download this Almanac and use it as a training tool.

The information carefully arranged by the author will definitely help them in their activities and also will be useful onboard ships and boats when used as the additional navigational publication. Just make sure you have a copy of the Almanac readily available at all times.

One more world popular and classic nautical publication. The content of this Almanac is traditionally arranged in several parts numbered for easier reference. The first part of the Almanac addresses the astronomical information and data that are commonly used every day by the navigators, together with the clear explanations on their use. The second part of the title is dedicated to the nautical tables and methods used.

The third part contains all required tables of tides for both home and foreign waters; the associated predictions were compiled by the recognized and reliable authorities. Then the part comes dealing with the coastal courses and distances covering the areas around the navigating channels of the British Isles and also near Europe. The fifth part of the Almanac contains the distance tables providing mariners with a worldwide coverage of the total distances between the major ports of US, Canada and Great Britain, and to all principal ports of the world.

The next part is dedicated to the legal issues, while the closing part of the volume deals only with the lights, buoys and beacons of the British Isles. The content of the publication has been carefully proofread and edited, and arrange in a way providing maximum accuracy and ease of reference. Another must-have one for literally every navigator.